Products

Products & Solutions

Marine Loading Arms

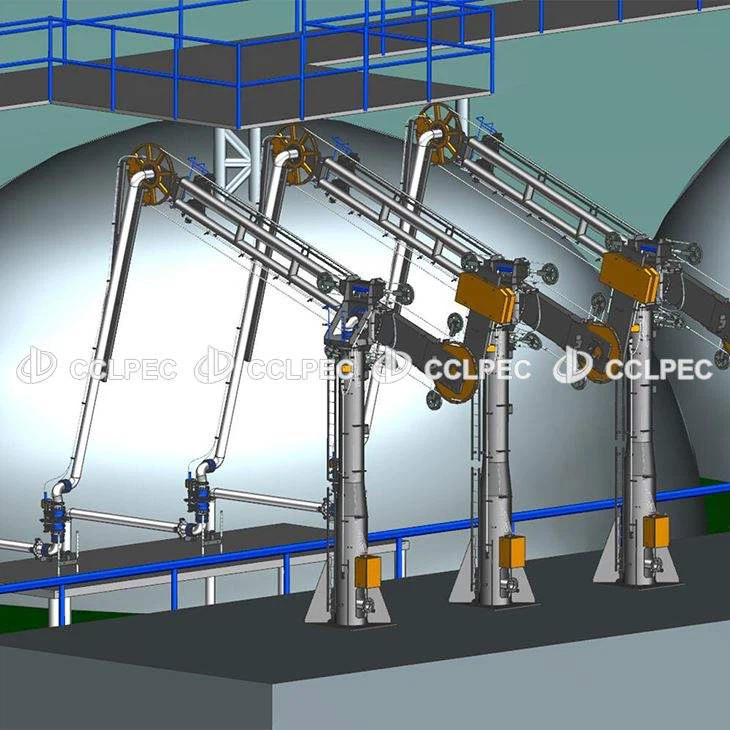

Marine Loading Arms are specialized equipment used for the loading and unloading of oil and gas from tankers. Our products feature an independent supporting structure to reduce stress on piping and swivel joints. Every unit is designed and manufactured in strict accordance with OCIMF and ISO 16904 standards.

Technical Highlights:

- Materials comply with U.S. and British standards

- Explosion-proof electrical components (ATEX/IEC certified)

- Certified by BV and SIL

- Strict supplier and quality control systems

- Remote fabrication monitoring available

Product Range

Marine Loading Arms

Marine loading arm(MLA) is usually installed on onshore terminal for loading and unloading gas and oil carried by tanker. Double raceways of swivel joints are processed by precision CNC machine and treated by nitriding. The rotating part of swivel joint is made of GCr15 with hardness of HRC60.

LNG Marine Loading Arm

The cryogenic fluid marine loading arm is a special equipment specially used for loading and unloading cryogenic media between tankers and terminal storage tanks, such as -104 ° C ethylene and -163 ° C LNG. The LNG marine loading arm is equipped with protection against ice falling to ensure the safety of operator.

Chemical Marine Loading Arm

The marine loading arm is installed on the wharf or floating dock, used to load and unload liquid between vessel tanker and storage tank of the receiving station. Compared with the loading hose, marine loading arm is rigid pipe structure, which is not easy to break and has a longer service life. The pipe material will be selected according to the medium properties to ensure the corrosion allowance.

Oil Marine Loading Arm

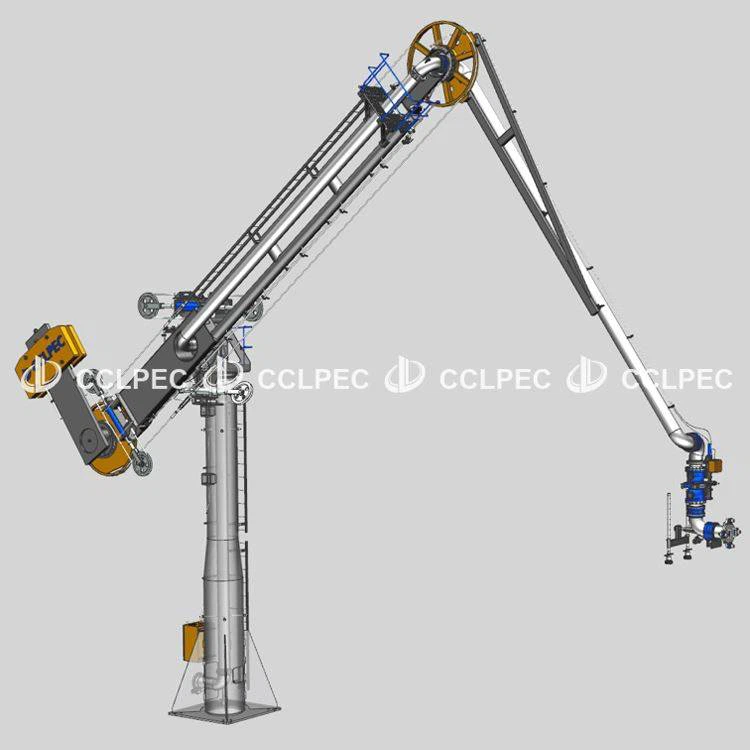

The marine loading arm is installed on the wharf or floating dock, used to load and unload the medium such as crude oil, petroleum and asphalt between the storage tank of receiving station and vessel tanker. The main components of MLA include: riser, trunnion box, support structure, piping, balanced transmission mechanism, counterweight system, triple swivel assembly, swivel joint, emergency release coupling (ERC), hydraulic / manual QCDC, hydraulic power unit (HPU), solenoid valve unit (SVU), local control panel (LCP), position monitoring system (PMS), and steam or electric heat tracing system (if needed), etc.

LPG Marine Loading Arm

CCL as a professional manufacturer of marine loadingarm, provides customers with professional marineloading solutions. The main components of MLAinclude: riser, trunnion box, support structure, pipeline,pulley system, counterweight system, triple swivelassembly, swivel joint, emergency release coupling(ERC), hydraulic / manual QCDC, hydraulic power Unit(HPU), solenoid valve unit (SVU), electrical system,position monitoring system (PMS), etc. The liquefiedpetroleum gas medium is divided into normaltemperature with high pressure, and low temperaturewith normal pressure. The pipeline material can be lowtemperature carbon steel or carbon steel.

Gasoline and Desiel Marine Loading Arm

The main components of marine loading arm include: riser, trunnion box, support structure, pipeline, balance transmission mechanism, counterweight system, triple swivel joint, swivel joint, emergency release coupling (ERC), hydraulic / manual QCDC, hydraulic power Unit (HPU), solenoid valve unit (SVU), local control panel (LCP), position monitoring system (PMS), etc. The pipe material will be selected according to the medium properties to ensure the corrosion allowance.

Acid Marine Loading Arm

Concentrated acids are usually highly corrosive, and some have other characteristics such as strong oxidizing and dehydrating abilities, which can cause severe chemical burns to the human body. Choosing the correct anti-corrosion material and the connection method of marine loading arm will provide customers with better and safer operation.

LNG Bunkering Loading Arm

Changlong has independently researched and developed the LNG bunkering arm, which is installed on the wharf or tanker and used to refuel LNG powered ships. The LNG bunkering arm is rigid connection, and break-away couplings are installed on each of the gas and liquid phase arms. When the connected tanker accidentally leaves the working area, the bunkering arm will be automatically disconnected from the ship, making the entire LNG refueling process safer.

Nowadays, loading hoses are still using in many wharfs, but due to the certain distance between the wharf and the vessel, and the connecting processes are labor-intensive, the hose will be difficult to connect. Moreover, compare to rigid pipe the hose is easy to break which makes its service life is relatively short. Our company’s new self-developed LNG bunkering loading arm can avoid upon problems. It has the advantages of easy operation, reasonable structure, and reliable performance.